Next Level Quality

Breathing life into watches, with a skill and sensitivity measured in microns.

Assembling the Mechanical Model Caliber 0200/0210.

Citizen Watch Manufacturing Inc.

Citizen Minami-Shinshu Watch Studio

Citizen Watch has the full range of watchmaking capabilities in-house, from crafting individual components to final assembly. Assembling the Mechanical Model Caliber 0200/0210 demands an extraordinary level of skill. Our specially accredited watchmaking Meisters need to deploy all their skill and sensitivity to bring these watches to life. We spoke to Super Meister Hiroko Arai and Meister Misato Kobayashi who are personally responsible for the all-important process of assembly.

Watch the movie

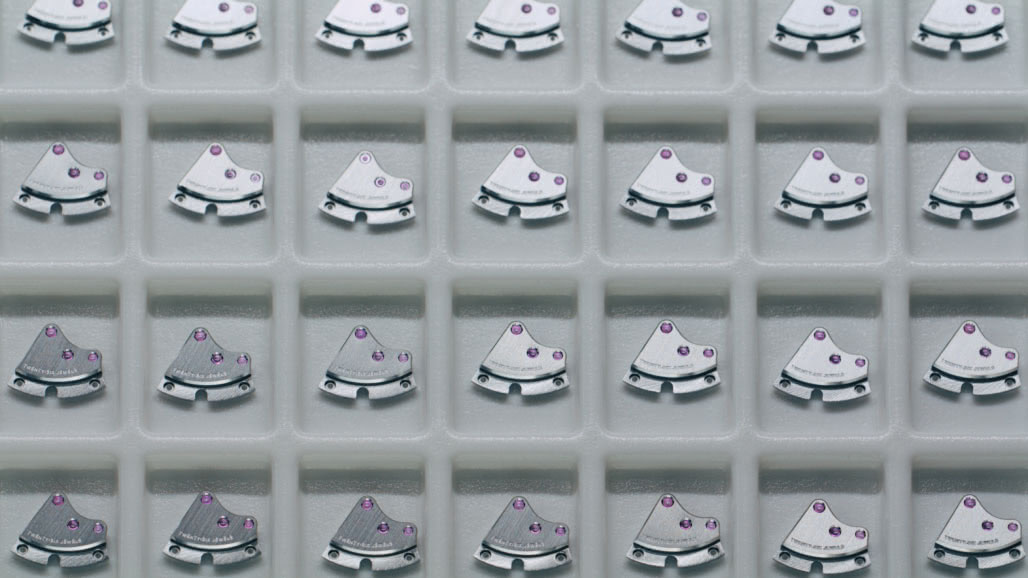

Assembling precise micron-scale parts.

One at a time. By hand.

I’ve heard that you, the Watchmaking Meisters, are the ones who get to assemble the Mechanical Model Caliber 0200/0210.

Arai: That’s right. The Meisters handle the assembly of The CITIZEN brand watches. Right now, I’m responsible for attaching the dial to the movement and then fitting the movement into the case. I do this for The CITIZEN brand watches, including the Caliber 0200 and 0210. For the first 15 years I worked here, I was responsible for final product assembly. For my next 20 years, I was assembling the module, a complication plate which sits on top of the movement. I then spent some time in the division responsible for mentoring and training; now I’ve come full circle and I‘m back in the division which handles final product assembly. This is actually my forty-fourth year at Citizen Watch.

Kobayashi: In my case, it’s my seventeenth year. I mainly handle the assembly of movements for our high-end watches like The CITIZEN brand. That includes the Caliber 0200/0210.

Assembling top-quality watches obviously requires greater precision. Is the assembly of The CITIZEN brand watches done entirely by hand?

Arai: Yes, it is. The CITIZEN brand watches have a large number of parts, regardless of whether they’re mechanical or light-powered with Eco-Drive. Since their size is measured in microns, we do everything by hand, from assembling the movement itself to casing the movement and attaching the hands to the dial.

As Meisters, you get to work on your own generously sized desks.

Arai: The CITIZEN is one of our high-end brands, as you know, so the pursuit of efficiency is not the be-all and end-all with it. You need to raise your concentration to an extremely high pitch to avoid wasting any of the carefully crafted and tiny components. That’s why we do the assembly work at our own private desks.

Is assembling The CITIZEN brand watches different from assembling other watches?

Arai: Of course, a high level of concentration is needed for any watch. With the Mechanical Model Caliber 0200/0210, the position where each individual component has to be mounted is determined with extreme precision. That’s particularly true when it comes to attaching the hands. Because the hour hand and the date mechanism are connected, you’ve got to attach the hour hand correctly at the spot where the date changes. It’s challenging to attach both the hands in a narrow gap just a few millimetres wide. You can’t take the hands out or take a second stab at the job; you get just the one chance to attach them right. On top of that, the hands have a beautiful shine, so making sure not to damage them when you put them into position is stressful.

Kobayashi: Other watches tend to get very difficult at a certain stage of assembly. What’s different about the Mechanical Model Caliber 0200/0210 is that there is literally no point in the process where you can relax! That’s why it’s difficult…. Psychologically, it’s pretty intense!

Despite the nerves and the difficulty, does it have its fun and rewarding aspects?

Kobayashi: The interesting thing with mechanical models like the Caliber 0200/0210 is seeing just how precisely you can make them run. The CITIZEN watches, whether mechanical or Eco-Drive, have loads of parts, so when you manage to assemble them nicely and without any waste or inefficiency, you’re like “I nailed it.”

So there’s a different kind of enjoyment to be had depending on the watch?

Kobayashi: I think so. Watches with complicated mechanisms have lots of parts, so they’re rewarding and worthwhile to assemble. Watches which are focused on thinness have fewer components, but because the watch has its own self-contained aesthetic, you need to raise your game. That’s an added element of psychological pressure, but it’s also fun.

Getting your mind into the right place before handling the components.

This is a job where sustained concentration is essential. Is that something you’re always working on?

Arai: Nothing’s more important than being in the right frame of mind. I always get here 40 or 45 minutes early so I can tidy up my desk. If I set off even five minutes late, the roads start getting clogged with rush-hour traffic and I start getting nervous about whether I’ll get to work on time…. That disrupts my mental rhythm, so I always try to get to work well in advance so that I have the time to do my breathing exercises.

So having some sort of a routine is important?

Arai: Certainly. Before starting work, I always clean my desk by wiping it in exactly the same way. Being able to sustain one’s concentration is crucial for this job, so I consciously try not to introduce changes into my lifestyle.

Kobayashi: I’m always careful not to work on an empty stomach. If you’re hungry, your mind goes to your stomach and your concentration suffers.

Arai: I’m the same. Food definitely matters. You’ve got to have a proper breakfast, lunch and dinner, not skip any meals, not eat before you go to bed. It’s all very basic stuff, but I’m pretty careful about maintaining the same rhythm to my life.

You were talking about cleaning your desk. I was impressed with how neatly and tidily your screwdrivers and tweezers were laid out on it. Do you use different tools for different watches?

Arai: Yes. With the Mechanical Model Caliber 0200/0210, every single screw is specially made. If you don’t use a driver that’s exactly the right fit, you’ll damage the screws. So yes, we use special tools for the Caliber 0200/0210.

What’s your relationship with your tools?

Arai: The Mechanical Model Caliber 0200/0210 is a highly sophisticated watch with a strong aesthetic, plus it has those lovely shiny hands. I clean my needle puller every day. It’s the same story with the tweezers I use to pick up the hands. I maintain and polish them every day so that they won’t leave any trace when I use them to attach the hands.

Is caring for your tools also part of your routine in a way?

Arai: Everyone carries out maintenance when work is finished for the day—that’s just a matter of course—but when I’m preparing things the next morning, I make a point of checking my tools all over again. If any aspect of your maintenance isn’t up to snuff, you’ve got to do it again…. It’s repetitive but you get used to it.

They are responsible for the last stage

in the watchmaking process.

For you, what’s the most important things about assembling watches?

Kobayashi: We have customers who buy our watches. I always try to put myself in their shoes. I try and judge if my work is good enough or not by asking myself whether I would be happy with the workmanship if I were buying the watch myself. People pay good money to buy our products, so the most important thing is for them to be happy with their purchases.

Do you have any techniques to help you get the customer perspective?

Arai: You tend to be more lenient when evaluating something you have made yourself. It’s inevitable. I try to stop that happening…. I try to bring in a different point of view when I’m halfway through the assembly process. I get the other Meisters to look at my work and I also take a very careful look at whatever they have assembled. Bringing a fresh pair of eyes to bear always helps you get the customer perspective.

Ms. Arai, in parallel with your regular assembly work, you also train up young talent. Is that one of the roles a Super Meister has?

Arai: Yes, it is. After first getting the designation of Meister, I was transferred to our watch school. It’s a department that helps raise the watchmaking skill level inside the company and helps people get qualifications. Everyone in the firm takes state-run technical proficiency examinations. Since returning to the department I’m in now, which assembles finished products, I do coaching. I also get dispatched to external workshops as an instructor.

There are several Meisters in Citizen, but you are the one and only Super Meister. Did getting the Super Meister designation affect your mental state?

Arai: I got the Super Meister title when I was 56. I remember feeling immense pressure at the time because I felt that a lot of the responsibility for the Citizen name had been dropped on me all of a sudden. When the company celebrated its one-hundredth anniversary in 2018, I traveled all over Japan to do watch-assembly demonstrations in front of live audiences. I was probably doing one or two per month. Everyone knew I had recently been designated a Super Meister, so I was extremely nervous, but when the demonstrations were over, people would come up to me and say things like, “I’ve become a true Citizen fan” or “I’m going to go out and buy one of those watches right now.” It was an opportunity for me to get a true sense of what my role is.

The spirit of the watch developer resides in the parts nobody sees.

As the person who assembles them, you have a unique perspective on the Mechanical Model Caliber 0200/0210. What’s its appeal in your eyes?

Arai: Although the Mechanical Model Caliber 0200/0210 is a simple watch, every time I assemble one, I’m reminded just how much presence and authority it has. When customers handle one, it’s the beauty of the hands and the dial that first jumps out and captivates them; then, when they look at the back, they’re dazzled not just by the rotor and the balance wheel, but by the handsome bridges on which so much attention has been lavished…. This is a watch you will cherish for a lifetime. It has a unique expression of its own.

Kobayashi: Something you learn when you assemble the Mechanical Model Caliber 0200/0210 is that every one of the components inside the watch is decorated. That’s quite astonishing. Every time I assemble one, I feel awestruck the whole time by the dedication of the movement design team at Citizen.

Because their commitment extends even to the parts no one ever sees?

Kobayashi: Exactly. Sadly, the customers won’t get to see these parts first-hand. And since repairs for The CITIZEN products are all handled by us, the manufacturer, no one from outside the company will ever get the chance to open up the movement. If they could take a look inside, they’d find a watch that’s fun, interesting and incredibly attentive to details. They’d be like, “I just can’t believe they went to the trouble of decorating all these tiny little components.”

This is my last question. What do you want to say to people who acquire a Mechanical Model Caliber 0200/0210?

Kobayashi: Maybe it’s a bit much to describe the watches as being like my own children…. Still, I do assemble them with all the care and meticulousness I would devote to bringing up a child of my own, so I very much hope the customers will cherish their Caliber 0200/0210 watches and use them for many years.

Arai: The Mechanical Model Caliber 0200/0210 is a high-quality watch. Even while I’m assembling them, I have the sense that it’s a watch that deserves to be a part of the owner’s whole life journey. And as the person who hand-assembles them, I want people to treat the watches with love and respect. That would make me happy.

About

The hand that makes the washi for the dial…

The hand that inspects the materials…

The hand that sketches the design…

The hand that assembles the watch…

Aspiring to be an integral part of your life.

In the pursuit of the next ideal in timekeeping,

The CITIZEN has a passion for making beautiful things.

The living embodiment of superior craftsmanship,

Our watches pass through a succession of skilled hands

Before reaching their ultimate destination:

the wrists of the wearers.

In Hand to Hand Story,

We highlight all the expert hands,

So dexterous, sensitive and thoughtful,

Required for the complex process of watchmaking.